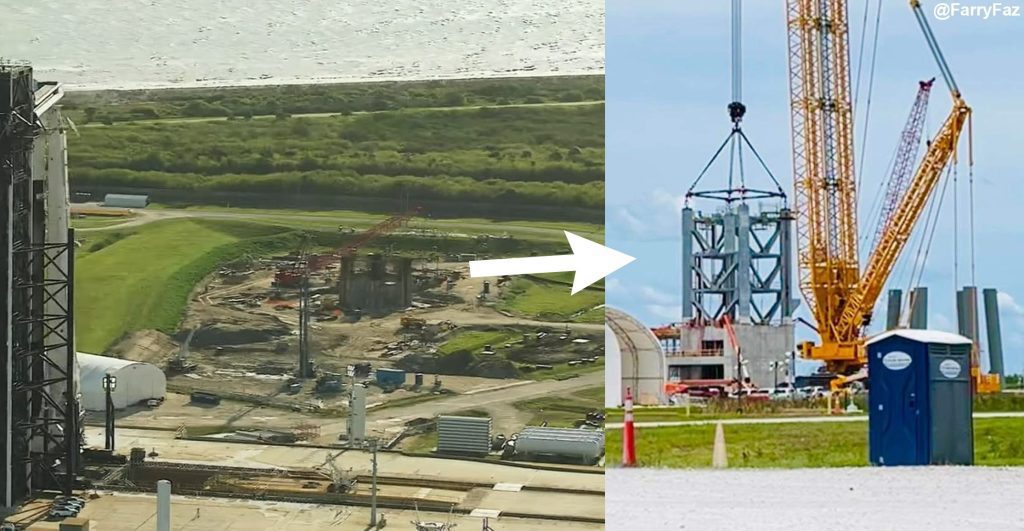

SpaceX has begun piling the first Starship launch tower in Florida.

Less than half a year after the company resumed work on the Starship launch pad located just a few hundred meters from the current Falcon launch facilities at NASA’s Kennedy Space Center’s LC-39A platform, a massive new launch tower is beginning to take shape. Once it reaches its final height, this tower will become the second tallest rocket-related building on the East Coast, having been surpassed only by the iconic and massive NASA Vehicle Assembly Building (VAB).

It could also reach that height very soon.

https://twitter.com/FarryFaz/status/1539310978721992705

For Starship’s Pad 39A facilities, SpaceX faces the unique challenge of organizing a major construction operation at one of the most active and important launch sites in the United States. Only in the first half of 2022, the LC-39A is on track to support 10 Falcon 9 launches, which imposes unique constraints on building the adjacent spacecraft platform. In partial response to those challenges, As previously discussed on TeslaratiSpaceX has taken lessons from Starbase, Texas and improved the assembly process for a number of pad components to reduce the amount of work that needs to be done on the pad itself.

For the first launch tower, SpaceX and its contractors moved with exceptional speed and took more than three months after work began on the first prefabricated section stacking the hull to its full height of approximately 146 meters (~480 ft). Each of the nine sections was basically barebones, however, reducing the amount of work before stacking, but complicating and increasing the amount of subsequent work required to turn the tower into something useful. For the first Starship launch tower in Florida, SpaceX spent more than three months meticulously assembling and equipping the first six parts of the nine prefab tower. Before first stack.

SpaceX sections began stacking on June 21, and they already contain a variety of handrails, elevator shafts, doorways, walkways, solid points, plumbing, and more pre-installation. While every section and all of the plumbing and shortened appliances will need to be connected after each stack, this process should be much easier and faster than the methods used at SpaceX in South Texas. Offsite, SpaceX is also making excellent progress assembling the orbital launch pad that looks like a cake and parts of the three giant booms that will eventually attach to the Starship’s first Florida launch tower — two to lift and catch rockets and a third to stabilize and refuel the spacecraft.

Just like the turret parts, there’s a good chance these Floridan components will be closer to completion than their Texas siblings when they finally head to the launch pad for installation. Additionally, if SpaceX’s experience in Texas is representative, the first Starship launch tower in Florida may reach its full height just a few months from now.

For the turret to be truly complete, SpaceX would need to finish and install three booms, and connect one of these arms to the ground supply of spacecraft gases and fuels on Pad 39A. Since the 39A never needed methane, the Starship’s fuel of choice, the move would also require the installation and activation of a new tank farm and plumbing systems capable of storing, “sub-cooling” quickly, and distributing at least a thousand tons (~2.2 million pounds) of liquid methane (LCH4). Starbase Florida is making great progress but there is still a significant amount of work going between SpaceX and preparing for launch.

“Avid problem solver. Extreme social media junkie. Beer buff. Coffee guru. Internet geek. Travel ninja.”

More Stories

In Greece Porsche 911 50th Anniversary – How much does it cost?

PS Plus: With a free Harry Potter game, the new season begins on the service

Sony set to unveil PS5 Pro before holiday season – Playstation